PREVENTATIVE MAINTENANCE SOFTWARE

Maximize control and minimize downtime by proactively tracking and scheduling maintenance of your machines and equipment.

FEATURES AND FUNCTIONALITY

Set up different preventative maintenance types

Schedule machine maintenance operations by usage, frequency of hours, or number of days

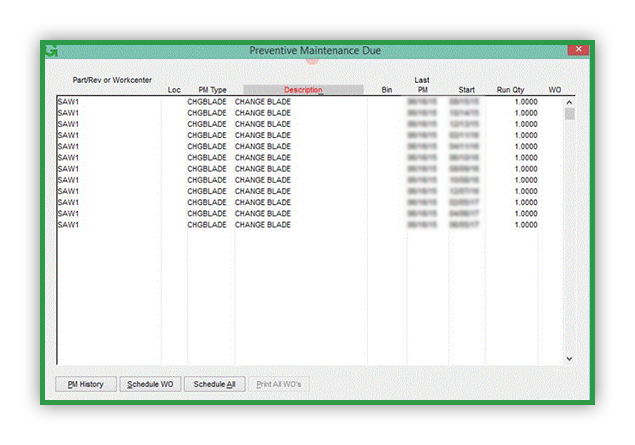

Generate preventative maintenance work orders by part, bin, or workcenter

Establish cutoff dates to limit the number of work orders generated

Schedule work orders weeks or months in advance

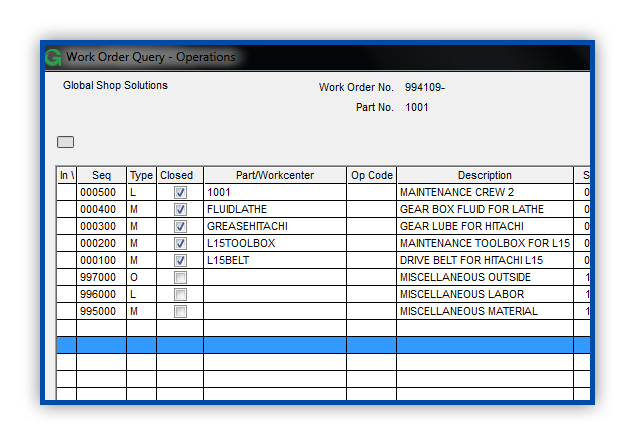

Cost history by equipment and tool

Tool and calibration management

Visibility and full documentation of scheduled maintenance

Work orders for parts are auto-generated by specified timeline

Set requirements for scheduling equipment repair

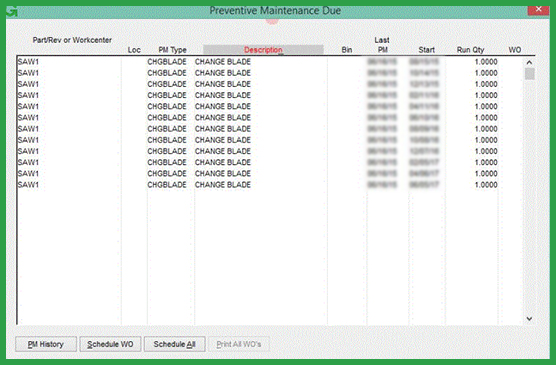

OPTIONS FOR YOUR MAINTENANCE

Describe procedures for each type of maintenance and schedule them based on frequency of hours, days, and more.

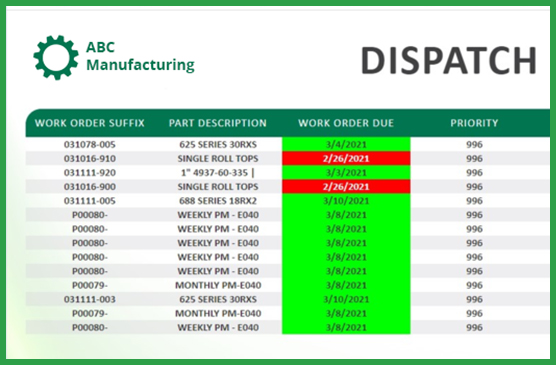

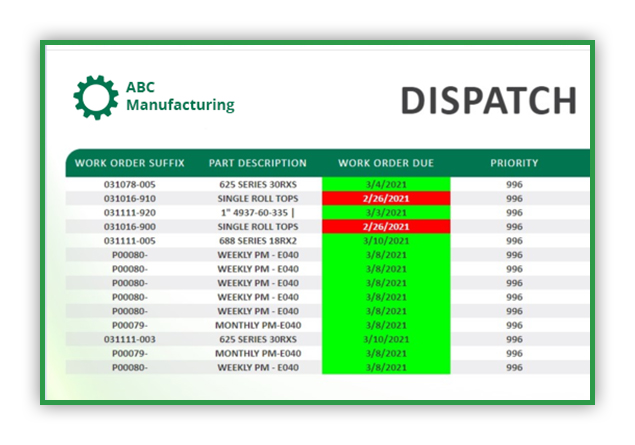

MANAGE WORK ORDERS FOR REPAIRS

Automatically schedule work orders for parts, repairs, or maintenance weeks or months in advance.

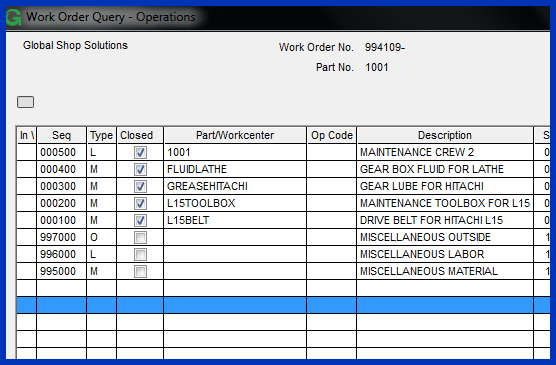

KNOW YOUR MAINTENANCE COSTS

See cost history by equipment and tool for better planning and cost savings.

OPTIONS FOR YOUR MAINTENANCE

Describe procedures for each type of maintenance and schedule them based on frequency of hours, days, and more.

MANAGE WORK ORDERS FOR REPAIRS

Automatically schedule work orders for parts, repairs, or maintenance weeks or months in advance.

KNOW YOUR MAINTENANCE COSTS

See cost history by equipment and tool for better planning and cost savings.