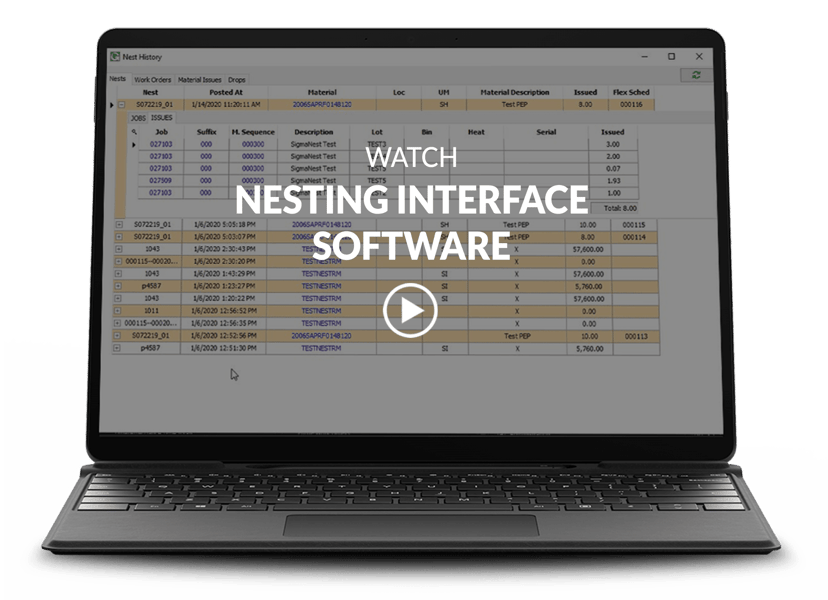

NESTING INTERFACE SOFTWARE

Integrate your shop floor cutting process with your ERP for simplified production.

FEATURES AND FUNCTIONALITY

Two-way communication

Track scrap

Get accurate material estimates

Reduce costs

Update estimates

Multiple work orders, one cutlist

Optimize production

Prevent material waste

Integrates with Global Shop Solutions cutlist application

Save labor hours including machine cut time

Receive and create material drops/remnants information

Schedule multiple work orders on the same workcenter

SEVERAL NESTING INTEGRATIONS

Choose your favorite integration that allows you to stream data between both software.

GET THE BEST USE OF MATERIAL

Know exactly how many work orders are in the queue that can fit on your current piece of material from inventory.

BETTER MANAGE DROPS AND SCRAP

Know exactly what material drops are left to place back in inventory or use for your next work orders and easily track scrap.

SEVERAL NESTING INTEGRATIONS

Choose your favorite integration that allows you to stream data between both software.

GET THE BEST USE OF MATERIAL

Know exactly how many work orders are in the queue that can fit on your current piece of material from inventory.

BETTER MANAGE DROPS AND SCRAP

Know exactly what material drops are left to place back in inventory or use for your next work orders and easily track scrap.