2 min read

RFID Improves Accuracy and Speed of Manufacturing Labor Data Collection

Admin December 15, 2016

As a software company, innovative thinking is near the core of our culture, so naturally we are always looking to improve for the better. One recent improvement in our manufacturing software stands out to me – the way our customers collect labor data. Switching to an RFID reader was a small change that was quick to implement and made a tremendous impact on our manufacturing customers’ daily operations, specifically an improvement in the accuracy and speed of labor collection.

Looking back, I can remember how I felt before we made this change. It was Monday morning, 6:45 am and just as I was about to clock in and get my day started, I yawned. When I scanned my thumbprint, I immediately got a hardware read error. The moisture from my yawn may have off-set my fingerprint. Frustrated, as I cleaned the biometric reader I remember thinking, “Is there a different way – maybe something easier?”

Every moment spent cleaning a biometric reader before clocking in is contradictory to the inefficiency we are working so hard to eradicate. Four years ago Global Shop Solutions headquarters upgraded to biometrics from hand-held barcode scanners, because we needed to stop fumbling through papers just to clock in. Now we have to fumble through lens cleaning wipes. Though it is an improvement for many, as we continue to grow we need something quicker, something that could handle our volume without disrupting production.

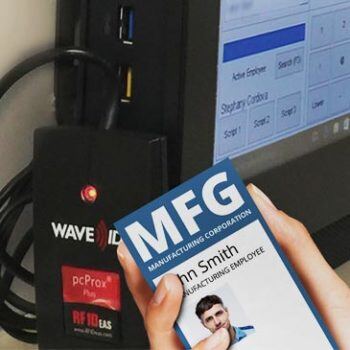

One day, Josh Withrow, Global Shop Solutions Consultant, presented a new project to the class and some of his fellow teammates. This project involved the use of radio-frequency identification, commonly referred to as RFID. RFID in short, uses radio waves to capture information and then store it in a tag. RFID readers have recently grown in popularity amongst our customer base. Global Shop Solutions is here to simplify your manufacturing; therefore, Josh quickly addressed the need to make these readers support functionalities in the software, such as labor collection. With a script written in our GAB SDK, he was able to provide this solution for our customers who owned these RFID readers.

At the Global Shop Solutions corporate headquarters, moving to RFID readers appeared to be the right decision for us as well because:

- We needed less mistakes in daily balancing.

- We needed to ensure all employees were wearing their badges at all times.

- We needed to remove small daily frustrations.

- We needed to give our employees dual confirmation when they clocked in.

- We needed to remain paperless.

- We needed our solution to be cost effective.

- We needed implementation to be quick and simple.

- We needed to simplify our business.

Within weeks Global Shop Solutions discarded our biometric devices and went live with RFID readers. The benefits were immediate.

Gone were the days of several people standing in line to clock in or out, discarding endless amounts of lens cleaner wipes, and yelling at hardware because it “didn’t like our thumbs.” Although, it is quite amazing how many employees suddenly had past lives as spies and couldn’t use the thumb reader because they “don’t have fingerprints anymore.”

Timeclock adjustments have significantly decreased and clocking in now takes a mere second. Each user is given dual confirmation of the capture with a ding sound as well as a pop-up text box reading that you have clocked in or out. The look of the hardware is sleek and cutting edge. The cost of the hardware was 60% less than our previous installations and the implementation was a breeze. Overall, the transition into the new way we collect labor has been a great success.

Thinking about making a change in the way you collect your labor? Contact us to find out which solution is right for you.