Founded in 1976, Alexandria Pro-Fab started out with one used welding machine in the back of a rented shop. Over the past 40 years, it has grown into one of the Midwest’s leading contract machine shops, with more than 150 employees operating out of 100,000 square feet of production space.

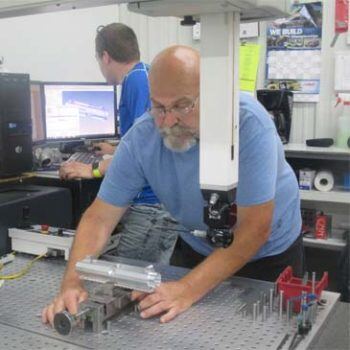

Located in Alexandria, Minnesota, Alexandria Pro-Fab’s custom machining services include precision CNC turning and milling, 5-axis milling, and prototypes. Their skilled operators work with a variety of materials, ranging from steel and stainless steel to aluminum, brass, alloys and plastics, as well as castings and forgings.

Near-100% On-Time Delivery

Global Shop Solutions’ powerful Advanced Planning & Scheduling (APS) application helps Alexandria Pro-Fab meet deadlines and run on time.

With APS, we can easily see where we have available time on our machines in case we need to move up a job or push others out.

Dave Dahl, Plant Manager at Alexandria Pro-Fab Co., Inc.

This allows Alexandria Pro-Fab to be flexible and they are able to rush orders without high levels of stress. With a near-100% on-time delivery, customers are happy and Alexandria Pro-Fab is maximizing work orders.

Inventorying Partial Jobs with Precision

Alexandria Pro-Fab runs upwards of 3,000 jobs through the shop floor each year. All of these jobs are tough to manage because, like many other manufacturers, the company also stocks finished products for some of its customers. Many times, Alexandria Pro-Fab starts manufacturing products well in advance of the due dates. These jobs are often partially finished, but Dahl explains how Global Shop Solutions is up for the task, “It might take several weeks to complete a job, but we need to WIP them in every two or three days in order to ship them. With Global Shop Solutions, we know at any point in time how many partials we have, where they are, and how many more we need to complete the job.”

ERP Software's Ease of Use

Accounting team member, Trent Sutherland, raves about how he can easily use the software to complete various tasks. “Since I’m in charge of maintaining the system, I also like the software’s ease of use,” says Sutherland. “The screens are very well laid out so that the information flows the way you need it to. And when a new employee comes aboard, it doesn’t take months to train them. It’s so easy to find the information that I just show them the basics and they can figure out a lot of stuff on their own.”

With on-time delivery, inventory precision, and ease of use, Global Shop Solutions helps Alexandria Pro-Fab grow and become more successful. You can download their full case study here.