Redefining Efficiency: The Evolution of ERP in Smart Manufacturing

Smart manufacturing used to sound like a buzzword – or a future so distant, it belonged to sci-fi. But the dawn of Industry 4.0, GenAI and digital transformation have kicked down the doors, bringing game-changing technology to factory floors now.

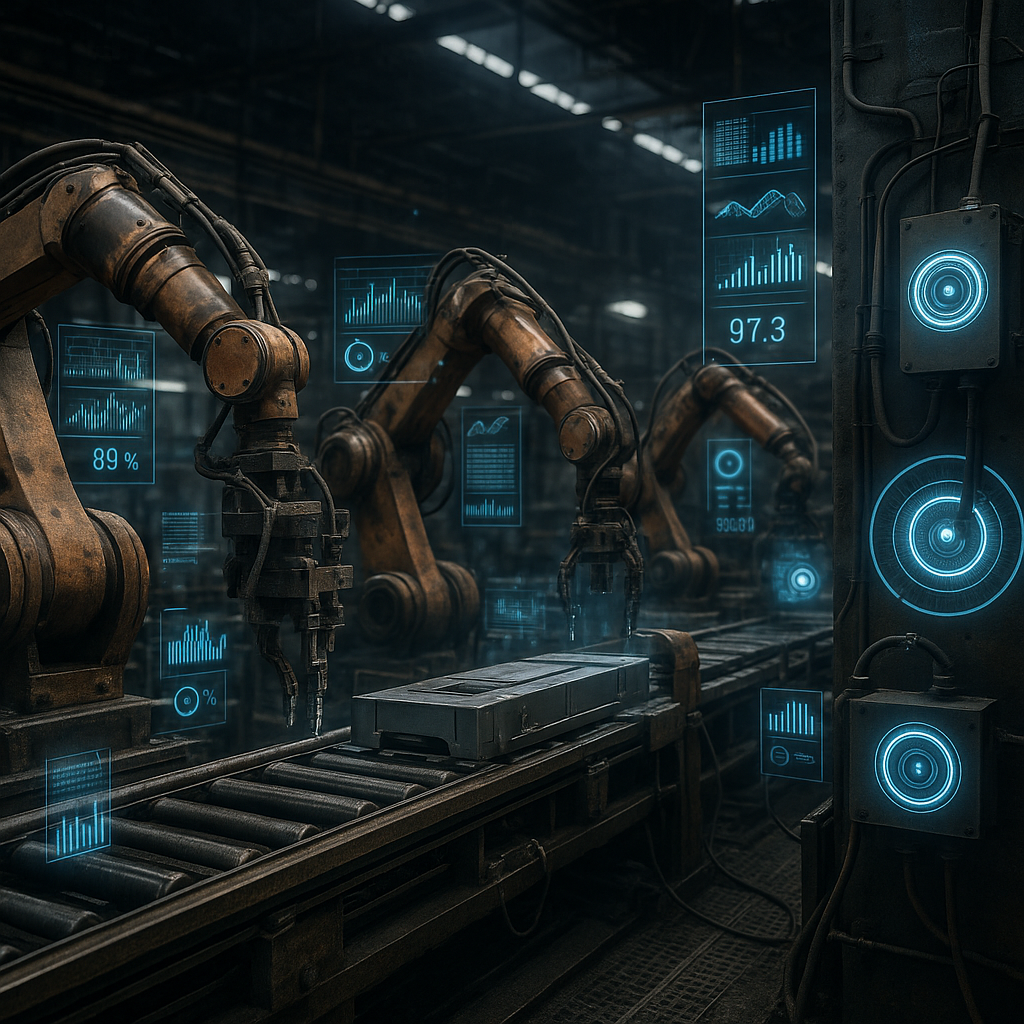

At the heart of this change is ERP software, evolving from a back-end ledger keeper to the digital conductor of fully connected manufacturing operations. In modern plants, classic efficiency isn’t enough – being smart means using automation, sensors, and advanced analytics to continually optimize every process without human micromanagement. ERP platforms enable this leap. By integrating data from robots, sensors and machine controls with business operations, manufacturers are turning waves of raw shop floor data into lightning-fast decisions and hands-off process improvements.

The top manufacturers aren’t just running faster; they’re running smarter, proactively flagging bottlenecks, predicting demand cycles and deploying resources before problems snowball. When your ERP system connects with smart manufacturing technologies, the benefits multiply: unplanned downtime drops, quality improve, and waste shrinks.

Unlocking Real-Time Insights: Data Integration Across the Factory Floor

Smart manufacturing’s true backbone is data, specifically, the constant data streaming from the shop floor to ERP and back again. As sensors monitor temperature, workflow and line speed, and as machines feed status updates with robotic precision, your ERP platform should display this ever-growing waterfall of data in ways that actually drive decisions.

Integrating smart devices and ERP surfaces the right information at the right time or even before you know you need it. With advanced dashboards, alerts and AI-enabled analytics, decision makers gain insight into every stage of production, maintenance and inventory. This real-time integration reveals hidden inefficiencies, root causes of scrap or downtime and immediate opportunities to save time or cash.

The best part? This data-driven clarity gives everyone from the corner office to the shop floor a single version of the truth. If a machine is running hot or a batch falls out of spec, the system knows and the team can respond immediately. Explore how ERP digital integration accelerates decision-making from these three manufacturers.

Driving Agility Through Connected Operations and Automation

Agility is now a survival skill in manufacturing. As markets shift and customer demands swing, agile manufacturers respond without missing a beat, thanks to tightly connected, highly automated ERP-driven operations. ERP systems power this agility by crossing department borders that used to hold data and teams hostage. Automated work orders, inventory requests and quality checks now move with the speed and accuracy of the smartest machine on the floor.

This interconnected workflow means fewer surprises and greater predictability. Need to ramp up production for a sudden order? Your ERP system orchestrates resources, shifts and material flows instantly, making manual rescheduling a thing of the past. As automation spreads across operations, ERP provides the framework for seamless handoffs: machine to machine, department to department and company to supply chain partner.

Forward-thinking manufacturers are leading the pack. Integrating ERP with smart devices and cloud platforms propels them into new markets and opportunities, all while keeping costs and complexity in check. For a closer look at how ERP and smart manufacturing drive agility, visit this overview.