Does your shop floor manager dread the announcement of changes or corrections to drawings? Do drawing and material list changes automatically translate into delays in production? It does not have to be that way. A CAD interface can eliminate those delays that have become the expected result of every change that needs to be accommodated in the process.

What Is Slowing Down Your Process?

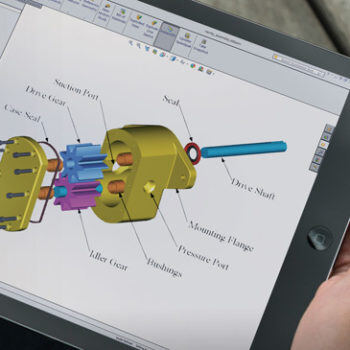

3D modeling in common CAD programs like SolidWorks®, Solid Edge™ and AutoCAD® have revolutionized the process on the engineering side. Changes can be updated simultaneously in every view of every drawing, eliminating the act of the engineer manually inputting data multiple times. At the same time the bill of materials (BOM) is being updated with the new information related to those changes. So why are there still delays every time drawings are changed?

The delay usually comes with the time required to transfer these changes from engineering to production. The BOM has to be manually updated to match the current version. New plans need to be printed and distributed to everyone who needs them to complete their part of the process.

CAD Interfaces Improve Project Time Ratios

A CAD interface that connects your CAD software to your ERP software eliminates this delay in transferring of documents related to a change. When the changes are complete to the drawings and BOM in engineering, it only takes a few clicks of a button to export the updated drawing and BOM from CAD to the shop floor ERP system.

As soon as the changes are completed on the engineering side, they can immediately be implemented throughout the production process. No waiting for data entry of the BOM changes. No waiting for new plans to be printed and distributed.

The other delays that are avoided through the efficiency of a CAD interface are the delays created from human error that inevitably accompanies any type of manual entry or human choice. The opportunity for data entry errors in the BOM is removed. No one on the shop floor can use the excuse that they didn’t have the newest version of the plans, or accidently picked up an outdated version.

No matter what 3D CAD program is being used, having a CAD interface is the solution to getting drawings and your BOM updated and out to the shop quickly and accurately. Using a CAD interface is a critical step to modernizing and simplifying your manufacturing process.