Does your shop manager still have piles of drawings in his office? Do errors occur because someone wasn’t using the latest revision of the drawings? Or maybe workers on the shop floor are waiting on new plans to be delivered and the bill of material (BOM) to be updated. All of these problems can be solved with a CAD Interface.

Changes Simplified with CAD

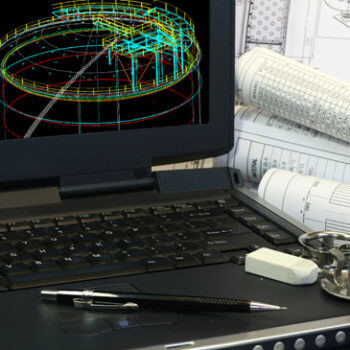

There are several different CAD programs being used by manufacturers to create drawings and the associated BOMs for the products being produced. SolidWorks®, Solid Edge™, and AutoCAD® are just a few of the CAD programs used by engineers to create drawings and BOMs. Each of these programs have simplified the process of the inevitable changes that go into the design of each piece. Digital changes through these CAD programs have lowered the costs of change implementation in both dollars and time.

Improve Efficiency with a CAD Interface

These CAD programs have improved efficiency on the engineering side of things. Yet, for many manufacturers, there still remains a gap that allows for human error and a delay in delivery of the information being generated so swiftly. That gap is in the manual transfer of data and drawings from the engineering department to the shop floor.

When the BOM from engineering is entered into your shop floor management system manually, it means redundant work and the opportunity for entry error, even with the most skilled data entry person. Changes to the plans mean changes to the BOM and more entry time and risk of errors.

The use of printed drawings also leaves room for error; it becomes easy for individuals to pick up an outdated set of plans or continue working off of old plans after changes have been made. Time is wasted printing out copies and looking for documents.

The solution to these problems is the use of a CAD interface that will transfer CAD drawings digitally from engineering to shop floor management. With a software interface that connects your CAD program to your ERP software, you create a simplified and seamless transfer of information. BOM details are electronically transferred from the CAD program to the ERP software for both the initial plans and updates from changes. CAD drawings are delivered digitally to the shop floor and viewable on their monitors. This ensures that the shop floor team is always viewing the most current version of the drawings.

Regardless of your CAD program, implementing a CAD interface for the transfer of engineering documents and data direct to your ERP software is a move towards simplifying your manufacturing and improving efficiency in your processes.