Every manufacturing business is an old friend of the quote-to-cash process. Yet, with never-ending changes in the market, this process takes new twists and turns. Here’s the silver lining: with ERP (Enterprise Resource Planning) software, manufacturers can take the struggle out of the quote-to-cash process. ERP software increases efficiency, drives business growth, and enhances competitiveness – ultimately winning the quote-to-cash game.

Implementing ERP software helps simplify the quote-to-cash process by providing a centralized platform to manage all aspects of customer interactions, production, and finances. It gathers, organizes and displays real-time data at every step of the process so you know what has happened with a job so far, where it is now, where it will go next, and when you can expect to ship it.

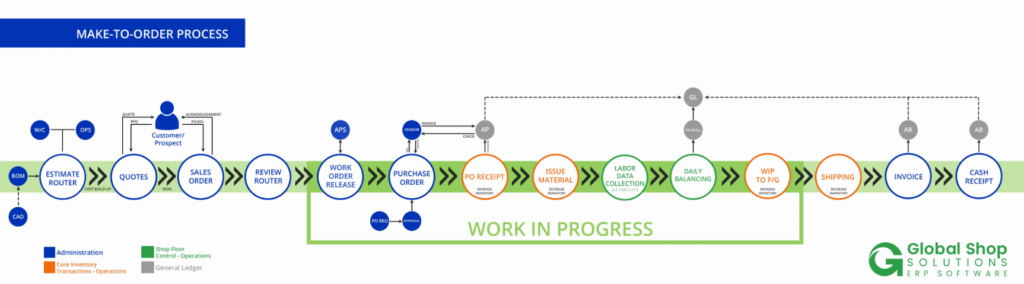

ERP Quote-to-Cash Process 101

Let’s dive into what quote-to-cash looks like – and how it works with ERP software.

1. Estimate Router & BOM

Few tasks are more important in the production process than creating an accurate, well-organized router to identify all materials required for the job, where they need to go, and when. That’s why the first step in the quote-to-cash process involves creating an estimated router and bill of materials (BOM). Here’s where an ERP Sales application with a strong Estimating tool makes getting started easy. You can use it to create quotes for your customers, including all relevant costs and details, showing your margins, and providing a jumping off point to estimate the specifics of the job.

ERP Estimating ensures two capabilities essential to you and your customers – speed and accuracy. With this software you can track your true costs in real time, generate detailed routers and BOMs, and quickly produce quotes using data you can trust. ERP also helps you get jobs to the shop floor quicker by automatically converting prospects to customer status and generating sales orders when you win quotes. It quickly adjusts estimates when material costs fluctuate, and easily quotes repeat orders using data already in your ERP. It also delivers quotes based on margins that satisfy your customer and your business.

BOMs are just as important for the first step because the list of manufactured and raw materials needed to build and assemble must be accurately entered onto the router. So must the equipment and tools needed to build the parts. Otherwise, data errors can affect every phase of the production process, from purchasing materials to final assembly of the product. ERP BOM software ensures accurate data for the router with the following features:

- Automatically import and export customer and CAD BOMs

- View inventory status of all BOM components and roll up their costs

- Easily identify additions, subtractions, or modifications to the BOM

- View consolidated parts lists

- Maintain an abbreviated parts master

- Simplify management of engineering revisions

- Easily compare engineering changes with BOM Compare software

- Automatically construct a full audit trail of all BOM changes

With ERP Estimating and BOM applications, you can ship complex assemblies on time and on budget while knowing your true costs when the job is complete.

2. Quotes

The next quote-to-cash step involves creating customer quotes, which are often made with some guesswork. ERP eliminates the need for guesswork by providing total clarity of every cost that goes into a job.

Schedulers and estimators can easily review information from similar jobs for comparison purposes, improving their ability to estimate setup and run times and making it easier to identify job costs and determine the amount of materials required.

The ERP Inventory application gives you more control over managing inventory costs by tracking inventory levels for stock and custom items with precision. Knowing inventory levels and availability at all times helps improve quoting accuracy and the ability to determine margins on every job.

Making profitable quotes requires knowing the specific costs for all components of a job as well as the total costs. The Job Costing Accounting application makes it easy by individually tracking freight, labor, overhead, outside services, other and materials. It also allows you to determine the precise costs of inventory, WIP and COGS by each of these components. With an ERP Quoting application your customers will know they received a fair price, and you will know your quotes are accurate, consistent and competitive.

3. Sales Order/Review Router

You’ve provided a quote and the customer has approved. Now it’s time to create the sales order and review the router to ensure everything is in order before starting production. The ERP Order Management application simplifies this process by tracking every step of the order processing from order entry to routing. Having comprehensive real-time data at your fingertips facilitates a clear and precise review process that results in accurate decision making that ensures smooth workflows, reduces labor costs, and minimizes human error.

ERP Order Management also improves shop floor efficiency with these and other capabilities:

- Accessing order data from anywhere at any time

- Cutting costs by automating manual processes

- Avoiding stockouts and overstocks with precise inventory tracking

- Automatically applying price changes to open orders

- Tracking orders shipped and invoiced in real time

If your business manufactures large, complex products or assemblies, an ERP Project Management application can be a lifesaver. Regardless of the size or scope of a project you can track and manage all the details to maximize your revenue, control cost, and complete the job on time.

You can control costs from start to finish by creating budgets to help manage estimated versus actual costs over the life of the project. You’ll know exactly where the project stands at any given time by viewing project status and completion percentage on one screen.

Whether the job is large or small, custom or stock, ERP helps you manage every aspect of your order management process to keep your business lean, efficient, transparent, and under control.

4. Work Order Release & Purchase Order Generation

Once a sales order is approved, it’s time to release a work order. The Shop Management ERP application with Routing and BOM tools helps you do just that, allowing you to release work orders, schedule jobs and team members, as well as track routing details. ERP brings it all together to ensure work orders are released on time and contain all necessary information, while generating the purchase order for your materials.

When your router and BOM are complete, ERP automatically generates and releases the digital work order, sending it directly to those who need it and tracking it in the Open Order Dashboard for all to see. Once the job is under way, Shop Management kicks into high gear by tracking a wide variety of important job performance data. This allows you to monitor and report on every phase of production from workcenter and scheduling data to setup reports, capacity planning, variance analysis and more.

ERP also saves time and reduces costs by allowing you to set up automated purchasing based on material requirements, planning functions, and purchase history. Automatic reorder points avoid stockouts by keeping inventories at suitable levels and make it easy to reschedule raw material deliveries when due dates change.

Here’s something new that further simplifies your material purchasing. It’s called an Automated Purchase Order Generation screen, and it uses a gridview to bring all your Auto Purchasing screens into one. This enables buyers to customize and analyze your full range of purchasing demand to make smart purchasing decisions. They can also sort data the way they want to see it, and make cost/vendor selections using simple drag-and-drop hierarchy. Cutting purchase orders goes much faster, and it’s never been easier to qualify raw material decisions by making informed reviews of purchased items.

Shop Management also provides a robust array of performance reports to help you keep production running smoothly and on time. These reports include real time information on material status, WIP, variance, backlog lists, work center efficiency, outside process scheduling, and other data essential to keeping people and jobs on track to ship on time.

5. PO Receipt, Issue Material and Collect Labor Data

Now that the admin work is done, it’s time to get the job into production. The Inventory and Purchasing ERP applications receive POs and issue all necessary material. They also track inventory levels and set reorder points to ensure you always have the necessary materials on hand to complete the order. ERP simplifies PO receiving by eliminating the need to click through multiple screens to find the data you want. Instead, you can access all the data you need from one screen, including all open POs, those due to be received today, and past due POs.

ERP Inventory application tracks every aspect of your material needs, including detailed inventory data, to achieve accurate physical inventory while managing costs. It helps manage your materials with multi-location inventory, cycle counting and product lines and usage reports.

Other features that ensure the right parts are issued to the right job on time include real-time inventory, bin, lot and serial number tracking, wireless data entry and barcode scanning, and forecasting for purchased and manufactured parts.

Collecting labor data is a cinch with the Shop Management application. The Labor Performance Dashboard lets you measure labor performance by employee, department, workcenter and more. You can efficiently manage labor costs by combining labor measurement and workforce performance data into one screen.

6. WIP to FG, Shipping, Invoice, and Cash Receipt

The final steps include completing the work to your finished goods, shipping it to the customer, and invoicing and collecting payment. With all the data you’ve collected from Job Costing Accounting, Order Management, Shop Management, Inventory and other ERP applications, you easily perform the last few steps. All that’s left is to track current Work-in-Process (WIP) to Finished Goods (FG), create and print shipping labels and documents, generate and send invoices, and track cash receipts.

From a customer satisfaction viewpoint, the most important step in this phase of the project is making sure the shipment goes out on time. The Shipping application makes it easy to stage, pack and ship the product quickly and efficiently by integrating directly with your third-party shipping software. Importing and exporting data with your shipper saves time and cuts cost by reducing double data entry and human error. Most important, you earn the trust of your customers by shipping on time and correctly every time.

Manufacturers that sell product directly from their web site can simplify the invoicing/payment process with the ERP eCommerce application. Features such as online order processing, electronic billing, instant payment options, and website integrations give your customers the ultimate in convenience while improving your cash flow.

The Future of Manufacturing

With manufacturing technologies advancing at a rapid pace, small to medium-sized manufacturers must adapt and embrace new technologies in order to compete and grow in the marketplace. One of the biggest trends is the use of automation and robotics. As automation technology becomes more accessible, more manufacturers are incorporating it into their production processes. By doing so, they can increase efficiency and productivity, reduce costs, and improve quality control.

Another trend shaping the future is Industry 4.0 – the next phase of the industrial revolution where manufacturing becomes fully connected and digitalized. With Industry 4.0, manufacturers can collect and analyze vast amounts of data in real-time, using it to optimize production processes and improve decision-making. Manufacturers who adopt Industry 4.0 technologies will be better equipped to stay competitive and meet ever-changing customer and market demands.

Now that you understand the quote-to-cash process and how it will play into the future of manufacturing, you must adapt to new technology. Implementing ERP software will get you there by continuously improving your processes and providing insights that keep you there.

Want to know how well you’re doing with handling the quote-to-cash steps? Take the manufacturing health test to see what you need: Manufacturing Health Test.

USA

USA

United States

United States Indonesia

Indonesia Mexico

Mexico Australia

Australia United Kingdom

United Kingdom New Zealand

New Zealand Singapore

Singapore