How to Get Your Quality Right

Is This You?

Handwritten routers and work orders are frequently incorrect

Engineers and machinists often work off different document versions

Quality inspections are an “after-the-fact” rather than a real-time process

Machinists log scrap and rework by hand and on paper

Beginning-to-end traceability of parts is impossible

The same quality issues occur over and over

You can’t determine your cost of quality with any precision

Bad parts are identified when customers return them, rather than before they ship

Lose customers due to recurring quality issues

Be better

Electronically deliver error-free routers and work orders to the shop floor

Engineers and machinists always work off the correct document rev

Identify bad parts as they’re made, rather than after they ship

Easily and accurately log all purchasing, inventory and manufacturing rejects

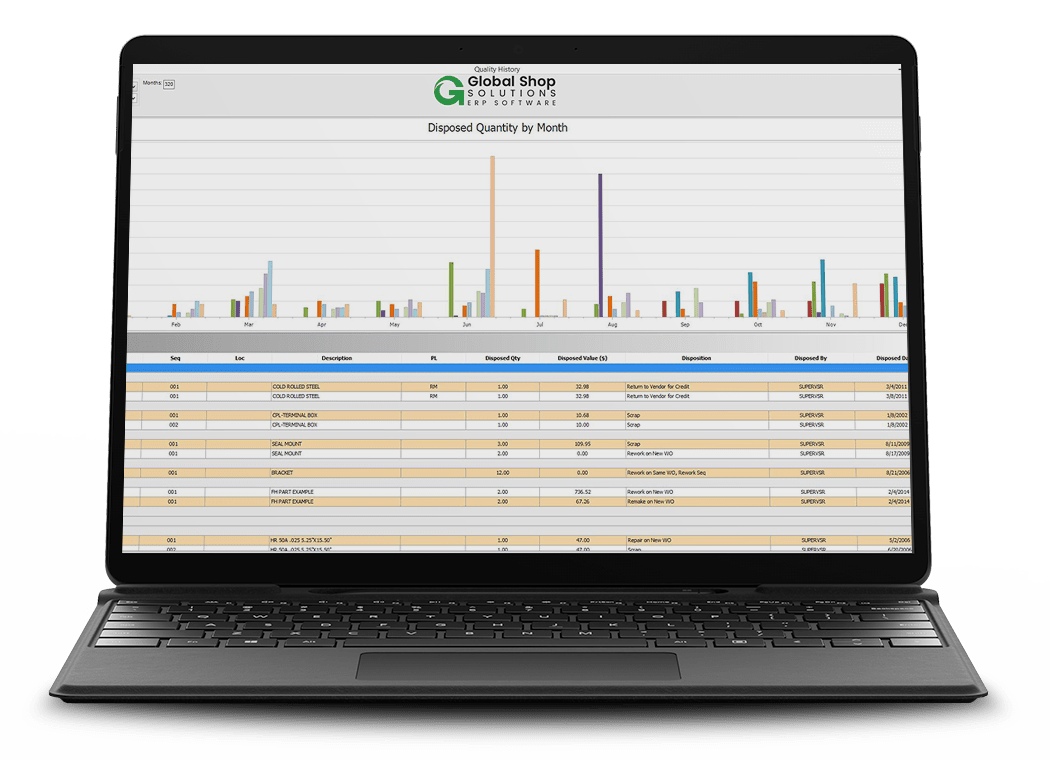

View all rework, rejects and scraps in one quality dashboard

Trace every part with 100% accuracy as it moves through the shop floor

Track your entire quality history in one central location

Easily produce quality documentation for ISO and other compliance auditors

Know the true cost of your quality - by part, job and overall

A few of the modules you will need

A few of the modules you will need

You can do it too

Download the case study to read how our customer Clockspring|NRI transformed quality from an anchor on their business into a competitive advantage.

“We now know what it costs to remake a part and our total cost of quality. As a result, we know what we’re really spending to manufacture our products.”

— Clockspring|NRI

USA

USA

United States

United States Indonesia

Indonesia Mexico

Mexico Australia

Australia United Kingdom

United Kingdom New Zealand

New Zealand Singapore

Singapore