How to get Accurate Inventory

Is This You?

Inventory is received and tracked by hand

People often have to climb over bins and shelves to find parts

Physical inventory counts take days and are rarely accurate

Pick and move tickets are written on paper and manually tracked

Materials are often late getting to the job

Jobs are late due to frequent part and material stockouts

Expedited material shipping charges are out of hand

Complete traceability of parts is next to impossible

We can only guess at our true inventory costs

Be better

All incoming materials are barcoded and instantly logged into inventory

Know exactly what you have in inventory and where it is

Rarely do physical inventory counts; if we do, they are swift and accurate

Mobile tech makes material movement a snap from anywhere

Auto reorder levels prevent stockouts of critical parts and materials

Jobs are never late due to lack of raw materials

Lot bin tracking gives complete traceability of parts

Rarely pay expedited shipping charges for incoming materials

Cycle counting allows us to purchase and use inventory more cost-effectively

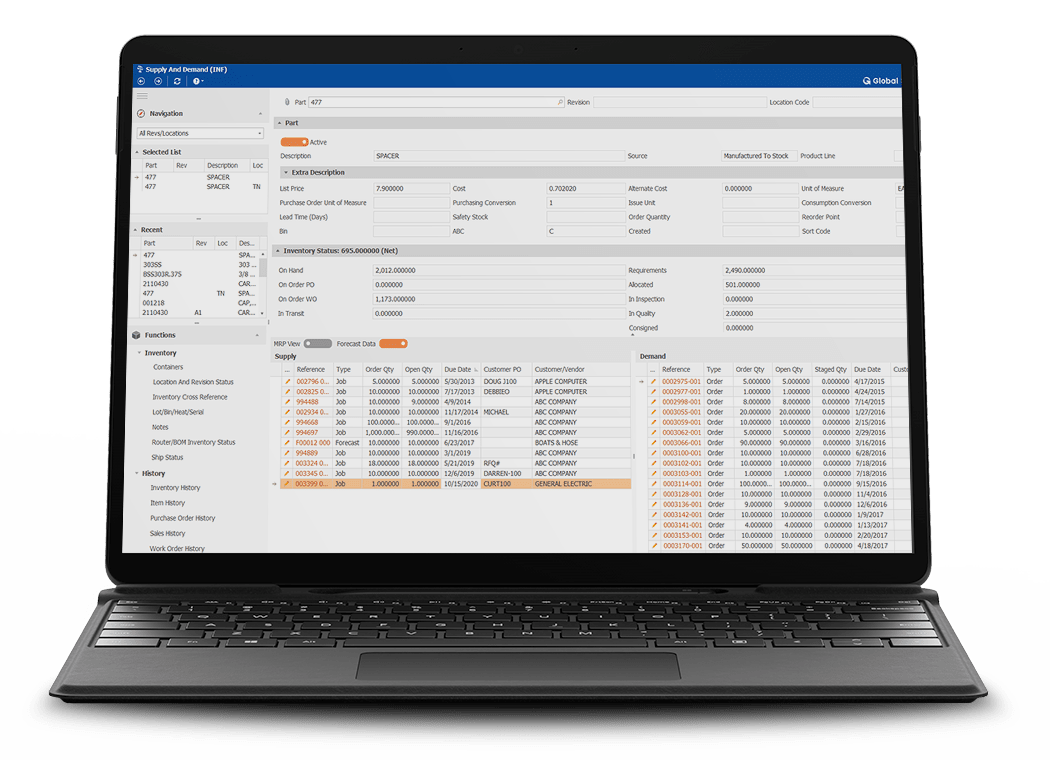

A few of the modules you will need

A few of the modules you will need

You can do it too

Download the case study to read how our customer Advanced Plastiform, Inc. turned inventory accuracy into the status quo rather than an unrealized dream.

“We know in real time the exact location of more than 4,000 items across three manufacturing facilities, and what’s in transit between them.”

— Advanced Plastiform, Inc.

USA

USA

United States

United States Indonesia

Indonesia Mexico

Mexico Australia

Australia United Kingdom

United Kingdom New Zealand

New Zealand Singapore

Singapore