Job Costing Accounting Software

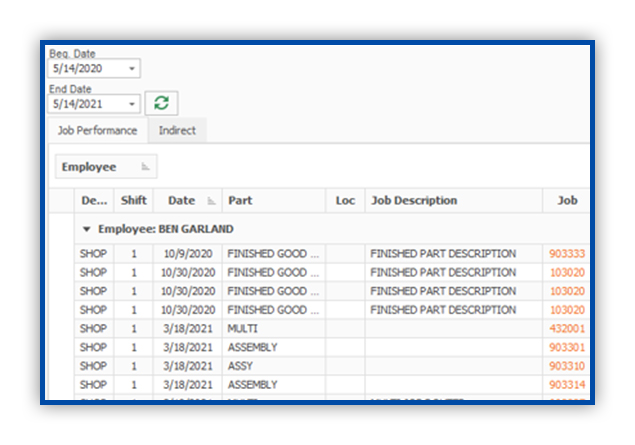

Measure cost components by Freight, Labor, Overhead, Outside Services, Other and Material (FLOOOM).

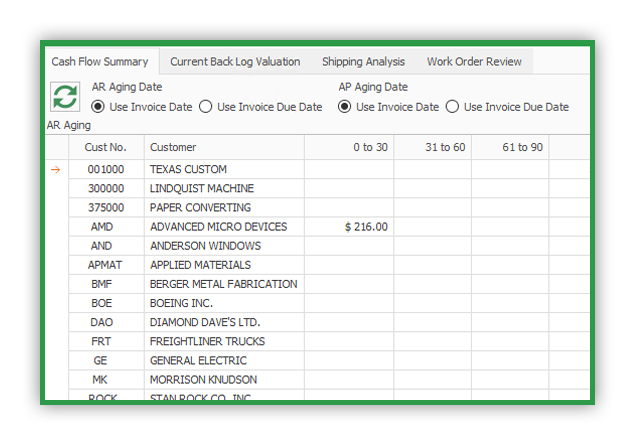

Know cost breakdown for inventory, WIP and COGS by FLOOOM components.

View the history of FG costs including old quantities, current transaction, new quantity and the cost for each.

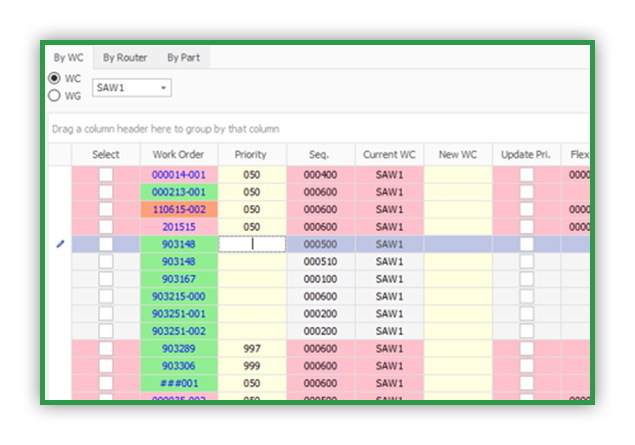

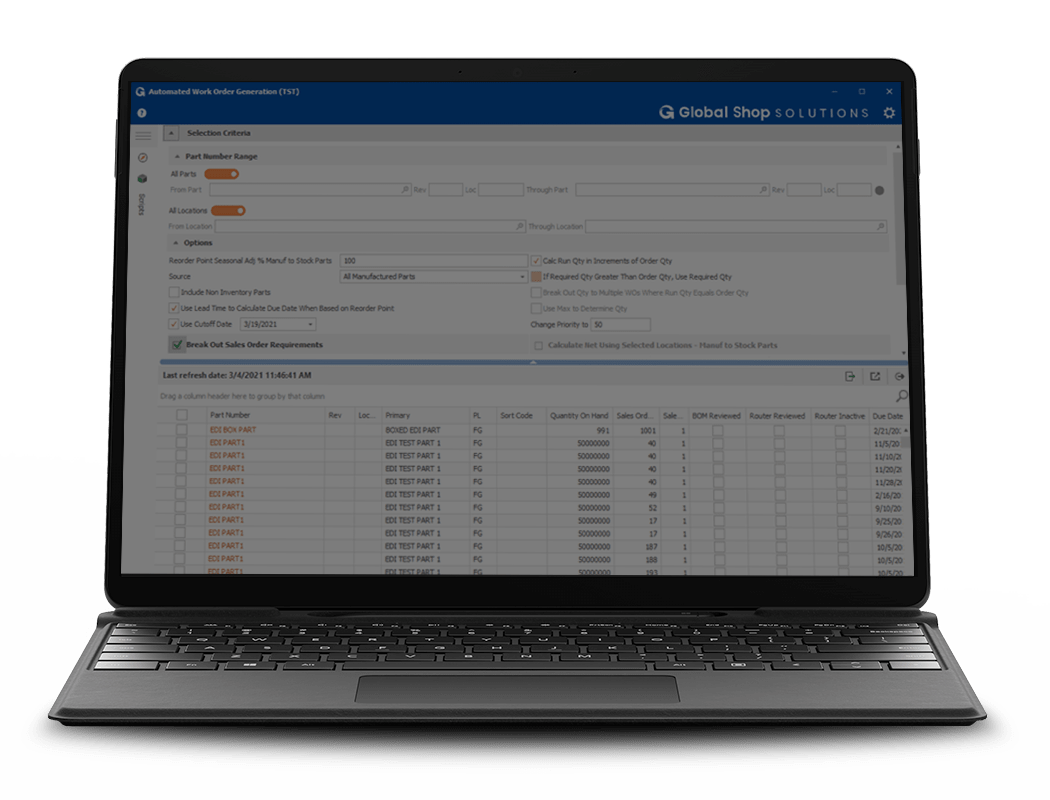

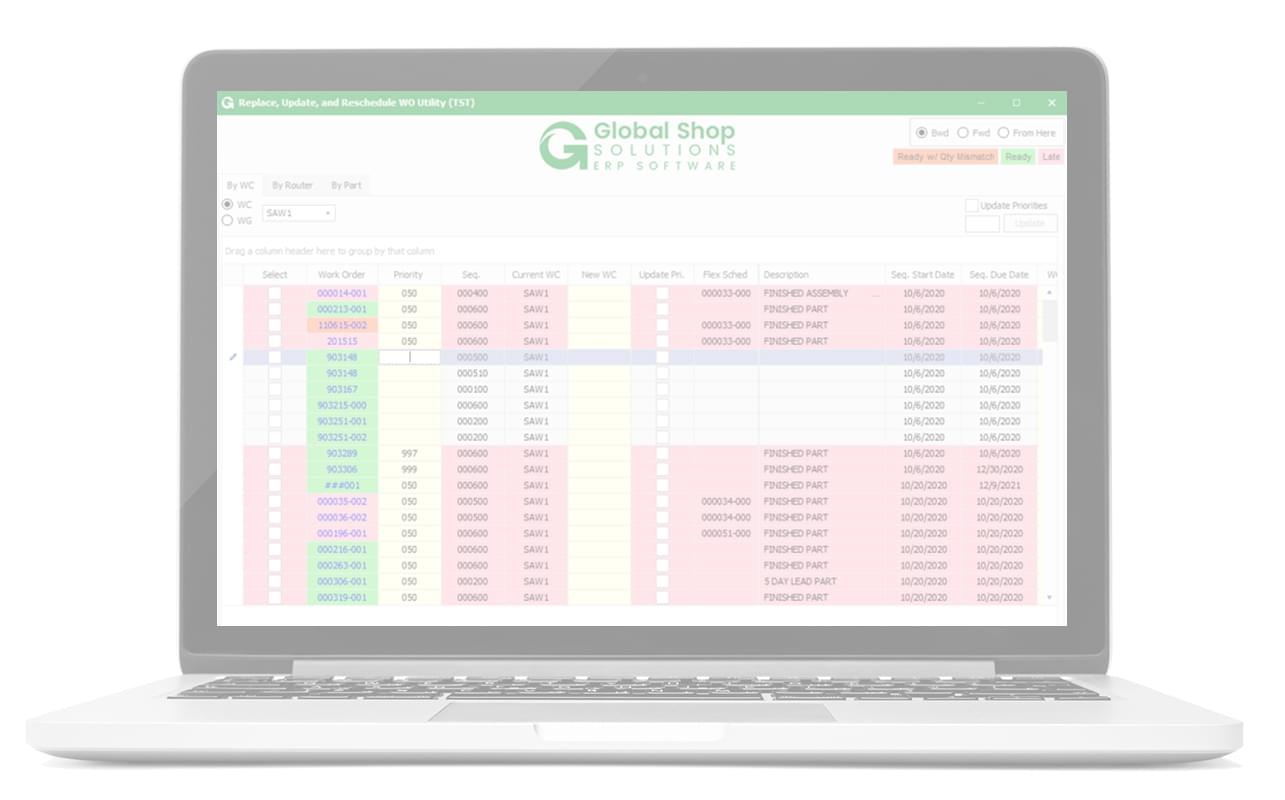

Sort, filter and drill down into data for the specific details you need.